Nuclear waste from small modular reactors

Lindsay M. Krall https://orcid.org/0000-0002-6962-7608 - Lindsay.M.Krall@gmail.com,

Allison M. Macfarlane https://orcid.org/0000-0002-8359-9324, and

Rodney C. Ewing https://orcid.org/0000-0001-9472-4031

Authors Info & Affiliations

edited by Eric J. Schelter, University of Pennsylvania, Philadelphia, PA;

received June 26, 2021;

accepted March 17, 2022 by Editorial Board Member Peter J. Rossky

May 31, 2022

119 (23) e2111833119

https://doi.org/10.1073/pnas.2111833119

Excerpts

Abbreviations

HLW High Level Waste

LWR light water reactor

PWR pressurized water reactor

SMR small modular reactor

SNF spent nuclear fuel

2.4. Waste Chemistry.

Whether a particular nuclear material can be stored or disposed of at a specific facility is, in part, governed by its radiochemical and bulk chemical compositions.

that react rapidly with water and/or atmospheric oxygen.

Since experience with handling and disposing of these chemically unstable waste streams is limited, we refer to decommissioning reports from previous experimental reactors to infer the implications that novel SMR materials will have for the direct disposal of their wastes (sections 4).

...

4. Management and Disposal of SMR Waste

The excess volume of SMR wastes will bear chemical and physical differences from PWR waste that will impact their

Although SMR developers tend to describe their waste production in terms of HLW or spent nuclear fuel mass and total radiotoxicity, repository design and postclosure safety analysis depend more on the

These parameters correlate to the waste stream radiochemistry and bulk chemical composition, which in turn, depend on the

which are different for SMRs than for PWRs.

4.1. spent nuclear fuel Management and Disposal.

4.1.1. Fuel composition and durability.

PWRs utilize ∼5 wt %–enriched 235U fuel bound in a durable (under reducing conditions) UO2 matrix contained within zirconium-clad fuel rods and supported by steel assembly structures. Over the course of irradiation, uranium atoms fission into a bimodal distribution of lighter fission products and transmute into heavier transuranic elements, such as plutonium. LWR fuel irradiated to a burnup of ∼50 MWd/kg contains ∼4 wt % fission products and ∼1 wt % plutonium, although these concentrations increase with the fuel burnup. In addition, the fuel cladding and assembly structural materials contain activation products formed through neutron absorption reactions.

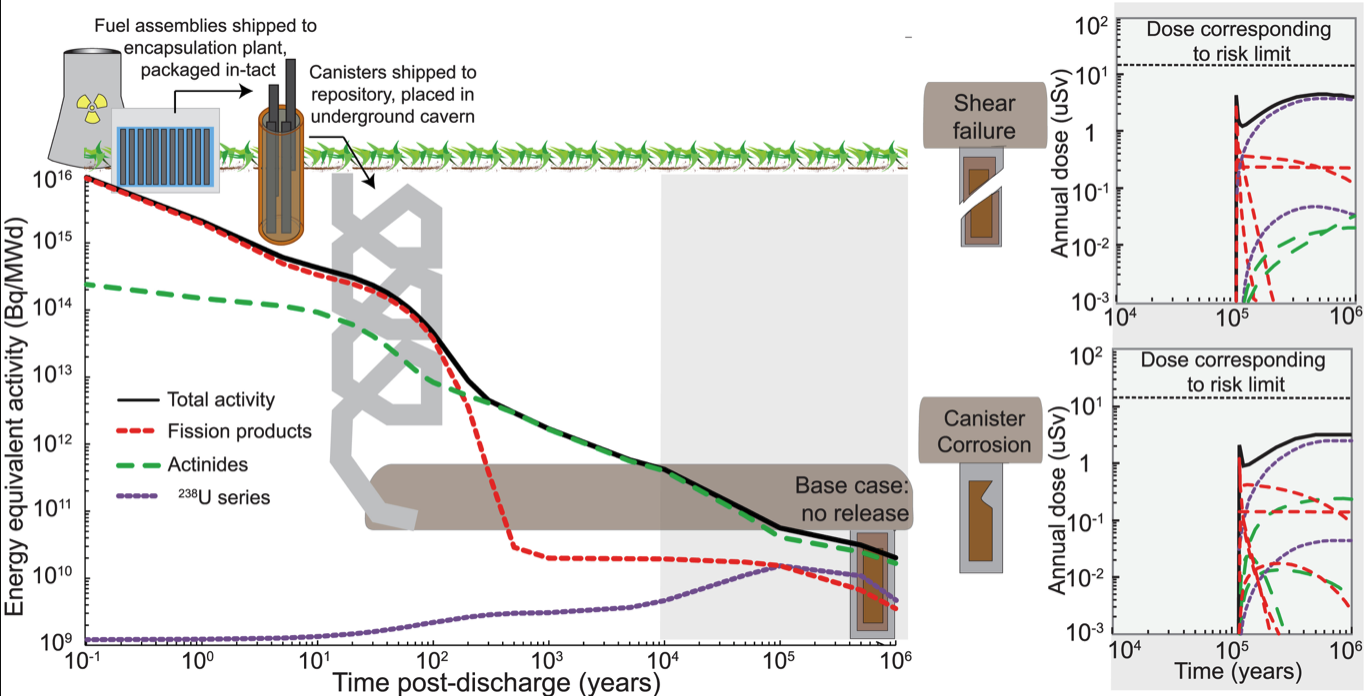

The fission products dominate the radioactivity, dose risk, and decay heat generation of newly discharged spent nuclear fuel, which is initially stored in actively cooled water pools to inhibit the physiochemical degradation of the fuel and cladding, otherwise driven by heat and radiation (Fig. 3).

Repository performance models indicate that long-lived geochemically mobile fission products, although a small fraction of the long-term spent nuclear fuel radioactivity, can deliver a significant portion of the far-field dose under several repository failure scenarios (Fig. 3 and section 4.1.2) (46, 47).

Fig. 3.

to enlarge click on figure

Temporal evolution of radioactivity in LWR fuel by contribution from fission products, actinides, and daughters in the uranium series (Left) as compared with calculated future doses under the two different scenarios of repository failure after 10,000 y (Right). Adapted from refs. 46 and 47.

OPEN IN VIEWER

The transuranic isotopes contain the bulk of the long-term spent nuclear fuel radioactivity (Fig. 3) but form a relatively small number of actinide elements, many of which are chemically bound in the UO2+X fuel matrix (48, 49). Therefore, the long-term chemical behavior of spent nuclear fuel in a geologic repository will be roughly analogous to that of crystalline UO2 (50). The solubility of uranium with respect to crystalline UO2 in pure pH-neutral water is very low, <10−9 M, although this increases to ∼10−7 M in the presence of dissolved oxygen (50–52).

Non-LWR SMRs will generate a similar array of radioisotopes for disposal but will employ fuels with markedly different bulk chemistries.

This unfavorable chemistry formed the basis of a US Department of Energy (DOE) decision to convert depleted uranium, stored as UF6, to a more stable uranium-oxide rather than dispose of the material as crystalline UF4 (56).

Sodium-cooled SMR designs employ a solid fuel, although for many of the designs listed in Table 1, this is envisioned to consist of stainless steel–clad uranium metal and elemental sodium, both of which classify as pyrophoric.

Although limited data are available to quantify the waste consequences associated with reprocessing and conditioning facilities, the following sections describe the implications for disposal of actinide- and fission product–containing SMR fuel.

4.1.2. Ingestion radiotoxicity vs. repository far-field dose.

Reactor developers sometimes compare the waste burden of different reactors and fuel cycles against the total “ingestion radiotoxicity” of their spent nuclear fuel or HLW. This metric, calculated in Sievert units, reflects the theoretical dose consequence of ingesting a particle of spent nuclear fuel or HLW, including all radionuclides present in the waste at a particular point in time (59). In the first ∼100 y postirradiation, the total radiotoxicity of LWR fuel is dominated by short-lived fission products, whereas 239Pu and 240Pu dominate the long-term spent nuclear fuel radiotoxicity (between 1,000 and 100,000 y postdischarge) (SI Appendix, section 2) (47).

Since the fraction of fission products in spent nuclear fuel is linearly proportional to the fuel burnup, the energy-equivalent fission product radiotoxicity is similar for low– and high–burnup SNF. However, low–burnup spent nuclear fuel contains a higher energy-equivalent concentration of 239Pu and 240Pu, so the radiotoxicity of iPWR spent nuclear fuel (burnup of 33 MWd/kg) is ∼50% higher than that of a PWR (burnup of 50 MWd/kg) at 10,000 y postdischarge (Fig. 4 and SI Appendix, section 2). A similar inverse relation between long-term actinide radiotoxicity and reactor size/burnup will prevail among small non-LWR SMRs, including thermal-spectrum molten salt reactors and sodium fast reactors (60). Fast reactors breed more plutonium than do thermal-spectrum reactors, so the spent nuclear fuel discharged by fast-spectrum SMRs will have a higher energy-equivalent long-term radiotoxicity than thermal-spectrum reactors (SI Appendix, section 2) (61).

Overall, SMRs will lead to an increase in long-term spent nuclear fuel ingestion radiotoxicity (Fig. 4).

Fig. 4.

to enlarge click on figure

“Radar” chart comparing waste calculation results for various SMRs normalized against respective results for a 3,400-MWth PWR displayed on a logarithmic axis.

This metric, however, provides little insight into future doses from a geologic repository, where various geochemical processes, complemented by multiple engineered barriers, can limit radionuclide transport from the repository to the surface ecosystem (47).

is important to limiting radionuclide advection rates and temporal variations in geochemistry.

Hydrogeochemical conditions are highly site specific but in general are most favorable at depths of a few hundred meters below Earth’s surface. If in the future, groundwater chemistry changes to a composition that destabilizes UO2+X, then many radionuclides will partition onto mineral surfaces through

This will further limit far-field radionuclide advection and consequent biological exposures (48, 49, 61).

Accounting for the geochemical mobility of the various radionuclides in SNF, repository evolution models typically attribute most of the dose consequence of a failed spent nuclear fuel canister to long-lived and geochemically mobile fission and activation products, namely 59Ni, 129I, 79Se, 36Cl, and 14C (Fig. 3) (48, 62).

Since the energy-equivalent activities of fission and activation products are similar for low– and high–burnup SNF, SMR fuel may not significantly increase the future exposure risks unless the spent nuclear fuel packaging (section 4.1.4) and site selection plans neglect the differences in actinide contents.

4.1.3. SNF/HLW thermal load and repository size.

After spent nuclear fuel is discharged from a reactor, decaying radionuclides in the fuel emit alpha, beta, and gamma radiation that is absorbed into nearby materials and converted to heat. To preserve the thermal hydraulic, mechanical, and chemical integrity of the repository system, the capacity and spacing of spent nuclear fuel disposal canisters will be configured to dissipate decay heat. Most repositories are designed to maintain temperatures less than 100 °C in the engineered barrier system. Yucca Mountain, however, was designed as a “hot” repository, wherein the temperature of groundwater would exceed the boiling point for a few hundred years postclosure. Consequently, repository dimensions—along with the associated packaging and excavation costs—are, in part, governed by decay heat rather than by waste volume (64, 65).

The duration of interim storage is factored into repository dimension calculations because the spent nuclear fuel decay power decreases over time. The predominant source of decay heat evolves from the fission products 137Cs and 90Sr and their 137mBa and 90Y daughters at 10 to 100 y postdischarge to 241Am and 238Pu at 100 to 1,000 y postdischarge (46).

In a repository that will accept SNF/HLW aged 20 to 60 y, near-field temperatures will peak at ∼10 y postclosure. Therefore, fission product decay heat imposes a significant constraint on repository dimensions (46, 66).

In a thermal-spectrum reactor, the energy-equivalent concentration of 238Pu increases with fuel burnup. Thus, for up to 100 y postdischarge, the energy-equivalent decay power is ∼30% higher for 50-MWd/kg burnup than for 33-MWd/kg spent nuclear fuel burnup (Fig. 4 and SI Appendix, section 2). The thermal character of low–burnup spent nuclear fuel implies that, despite the increased volumes associated with SMRs, their impact on the dimensions of an spent nuclear fuel repository may be small.

Models indicate that at 100 y postdischarge, the thermal output of spent nuclear fuel generated by a plutonium-fueled fast SMR (similar to the Toshiba 4S design) will be ∼50% higher than the energy-equivalent PWR fuel (Fig. 4 and SI Appendix, section 2).

Thermal data for uranium-fueled fast SMRs are scarce, although large sodium-cooled fast reactors (Table 1) are said to fission minor actinides, like 241Am and 238Pu, more efficiently than thermal-spectrum LWRs and molten salt reactors (61).

However, the persistence of short- and long-lived fission products in these fuel cycles will limit their theoretical benefit for repository dimensions.

HLW streams that predominately consist of fission products, typically conditioned into borosilicate glass, may require a repository up to 50% as large as a repository for LWR spent nuclear fuel (58). Since repository excavation and backfill account for only ∼10% of the cost of a decommissioning and spent nuclear fuel disposal program (66), a fuel cycle that seeks to reprocess Pu will not significantly reduce nuclear waste management and disposal costs.

4.1.4. Fissile isotopes and recriticality.

As a primary safety objective, spent nuclear fuel should be stored and disposed of in a subcritical configuration to inhibit its ability to sustain a fission chain reaction. Since the critical mass of water-moderated UO2 decreases exponentially if its fissile isotope concentration increases from 1 to 5% (figure 8 in ref. 67), the mass of spent nuclear fuel that can be loaded into a disposal package is limited by the concentration of fissile 235U, 239Pu, and 241Pu in the SNF. In LWR SNF, the net concentration of these isotopes correlates positively to initial fuel enrichment and negatively to final burnup. Calculations performed to assess long-term criticality safety for several geologic repository designs indicate that fresh 5 wt % 235U–enriched PWR fuel should be irradiated to a burnup >39 MWd/kg to maintain subcritical conditions in canisters loaded with four or more PWR assemblies (68–70).

Since iPWRs will irradiate 5 wt % 235U–enriched fuel to a burnup of <34 MWd/kg, iPWR spent nuclear fuel will not meet the criticality safety standards for existing repository designs (71–75) (Fig. 5 and SI Appendix, section 2). Likewise, sodium-cooled SMR designs, which call for irradiation of fresh fuel with ≫10 wt % 235U or 239Pu to burnups ranging from 10 to 100 MWd/kg, will generate spent nuclear fuel with high fissile isotope concentrations (Fig. 5, Table 1, and SI Appendix, section 2). Quoted fuel enrichments and burnups for molten salt SMR designs are more variable, and published depletion models that estimate the fissile isotope composition of the spent nuclear fuel are scarce. Therefore, we assumed that the isotopic evolutions of fuel in an LWR and a molten salt reactor are similar because both reactors operate under the thermal neutron spectrum. Under this assumption, spent nuclear fuel generated by the Terrestrial Energy IMSR-400, which calls for 3 wt % 235U–enriched fuel irradiated to a burnup of 14 MWd/kg, will contain 2.1 wt % 235U + 239Pu. Like that generated by the NuScale iPWR (2.3 wt %) and the Toshiba 4S SMR (17 wt %), this contains fissile isotopes in higher concentrations than the spent nuclear fuel generated by a PWR (1.3 wt %) (Fig. 4 and SI Appendix, section 2). The case is likely similar for many of the SMR designs listed in Table 1, considering the quoted fuel enrichments and burnups.

to enlarge click on figure

Concentration of fissile isotopes in spent nuclear fuel (“Fissile concentration”) vs. mass of fuel in each assembly (“Mass uranium”) for various reactors plotted alongside a criticality curve generated from the data of refs. 67, 72, and 73 to illustrate the sensitivity of spent nuclear fuel canister loading to the fissile isotope composition of the SNF. Inset shows enlargement of clustered points, labelled according to reactor-type and the associated initial fuel enrichment and burnup. Derivation of fissile concentration is explained in SI Appendix, section 2 or obtained from refs. 74 and 75. The molten salt SMR designs studied here contain several to tens of metric tons of uranium or thorium fuel that is not bound within structural assemblies and so, are here assigned an assembly mass similar to a PWR. "GE-PRISM" refers to the Power Reactor Innovative Small Module design by GE Hitachi Nuclear Energy.

In general, for a given spent nuclear fuel composition, each canister should contain a subcritical mass of SNF. However, critical masses are very small for materials containing more than a few weight percent fissile isotopes. Whereas a critical mass of PWR spent nuclear fuel is >1,000 kg, critical masses for iPWR and sodium-cooled SMR spent nuclear fuel are only ∼200 and <10 kg, respectively (Fig. 5). Recriticality boundaries and management processes are rarely assessed for unconventional spent nuclear fuel types with elevated fissile isotope concentrations. However, Hicks and Baldwin (71) indicate that spent nuclear fuel from the UK Prototype Fast Reactor would pose a recriticality risk even if disposal canister capacities were limited to a single spent nuclear fuel assembly (burnup of 190 MWd/kg, initial/final 239Pu concentrations of 30/15 wt %). Therefore, novel approaches to canister design and loading will need to be developed for the SMR designs analyzed here and listed in Table 1.

Canisters designed to accommodate the existing PWR spent nuclear fuel inventory have a capacity of four or more assemblies per canister, whereas canisters for iPWR and sodium-cooled SMR spent nuclear fuel might accommodate only one assembly or a fractional assembly, respectively.

Molten salt reactor spent nuclear fuel packaging will likewise deviate from the existing concepts. Vendors typically suggest that the spent liquid fuel salt remains inside the reactor vessels while it solidifies. However, the recriticality incident that almost occurred at the shutdown MSRE as a result of formation and migration of volatile actinide–fluoride complexes (section 3.4.3) (45) illustrates the need to process the actinides in this salt mass, including the fissile 235U, 239Pu, and/or 233U, into a more stable ceramic waste form. Although the DOE eventually accomplished this through a pilot-scale fluoride volatility treatment, no methods to segment and package the remainder of the fission product–containing MSRE salt mass have been developed, as illustrated by the DOE preference to entomb the MSRE on-site at Oak Ridge National Laboratory (section 3.4.3 and SI Appendix, section 3).

The need for spent nuclear fuel segmentation and/or a larger number of disposal canisters and associated packaging operations support the notion that the back end of SMR fuel cycles, as discussed in section 3, entails increased handling of radiologic and fissile material. These packaging challenges will be compounded by the relatively large, energy-equivalent volumes of SMR spent nuclear fuel (sections 1 and 3.2) and will introduce costs and radiation exposure risks to thenuclear fuel cycle.

4.2. LILW Management and Disposal.

SMRs will generate larger, energy-equivalent volumes of LILW than a PWR (Fig. 1 and sections 3.3 and 3.4). Some of this waste may be suited for disposal in a near-surface, short-lived LILW repository (<30-m deep) (7). However, neutron-activated, long-lived LILW is more complicated to manage because radiation exposures must be mitigated on both operational and geologic timescales.

Due in part to the need to limit worker exposures to the radiation emanating from activated LWR components, especially that emitted by the 60Co (t1/2 = 5.3 y) activation product of steel (76), decommissioning represents ∼20% of LWR waste management and disposal costs (67). Since SMRs will generate >10-fold more neutron-activated steel than the energy-equivalent LWR and will introduce the need to chemically treat radioactive sodium and molten salt coolants, they may significantly increase the costs and exposure risks associated with nuclear decommissioning.

After 60Co has decayed, activities of long-lived 59Ni, 63Ni, 14C, 94Nb, and 93Mo will remain sufficiently high to warrant the geologic disposal of activated LWR components (Table 2) (77). Nickel isotopes are soluble under acidic conditions (78), so cementitious barrier materials are employed in LILW repositories to impose alkaline conditions (79) that limit nickel dissolution in the repository groundwater (80). More mobile than nickel, models suggest that 14C and 93Mo will be the dominant contributors to future doses from a repository for activated decommissioning waste (81). Activated SMR and LWR steel will bear similar radiochemical compositions, so 14C and 93Mo may dominate future doses from SMR waste repositories, although such doses, like the energy-equivalent radionuclide inventory, may be higher for SMR wastes. Since few studies focused on constraining the radionuclide inventories of irradiated graphite, molten salt, and sodium are available, the future dose consequence for these waste streams remains unclear.

Version: 6.12.2022

Adresse dieser Seite